Tensioning Equipment

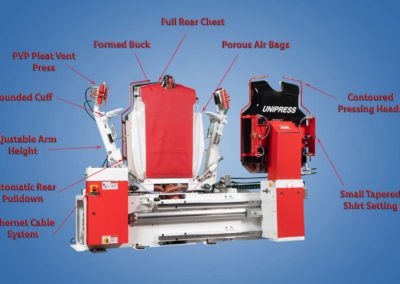

Unipress Tensioning Equipment has many great features. Our team is very knowledgeable and can help you determine which tensioning machine would be best for your needs.

Tensioning Equipment Features

- Improves Quality

- Increases Production

- Easy To Operate

- Built For Reliability And Ease Of Operation

What are the key features of Unipress Tensioning Equipment?

Unipress Tensioning Equipment is a renowned brand in the field of tensioning equipment. With their high-quality products and advanced technology, they have become a trusted choice for various industries. Let’s take a closer look at some of the key features that set Unipress Tensioning Equipment apart from others:

1. Versatility:Unipress offers a wide range of tensioning equipment suitable for different applications and industries. Whether you need to tension cables, wires, ropes, or even conveyor belts, Unipress has the right solution for your specific needs.

2. Precision and Accuracy: One of the standout features of Unipress Tensioning Equipment is its ability to provide precise and accurate tension control. This ensures that your materials are properly tensioned without any risk of overstretching or under-tensioning.

3. User-Friendly Design: Unipress understands the importance of ease-of-use in industrial settings. Their tensioning equipment is designed with user-friendly interfaces and intuitive controls, making it easy for operators to set up and operate the machines efficiently.

4. Durability and Reliability: When it comes to industrial equipment, durability is paramount. Unipress Tensioning Equipment is built to withstand harsh operating conditions and heavy usage over time. Their products are known for their robust construction and long-lasting performance.

5. Safety Features: Safety should always be a top priority in any industrial setting. Unipress incorporates various safety features into their tensioning equipment to ensure operator protection during operation. These include emergency stop buttons, overload protection mechanisms, and comprehensive safety protocols.

6. Customization Options: Every industry has its unique requirements when it comes to tensioning applications. Unipress offers customization options that allow customers to tailor their equipment according to their specific needs.

In conclusion, Unipress Tensioning Equipment stands out in the market due to its versatility, precision, user-friendly design, durability, safety features, and customization options. By choosing Unipress, industries can ensure efficient and reliable tensioning operations for their various applications.

How can Unipress Tensioning Equipment benefit different industries?

Unipress Tensioning Equipment is a versatile and innovative solution that offers numerous benefits across various industries. This advanced equipment is designed to provide precise and reliable tensioning for a wide range of applications, ensuring optimal performance and efficiency.

One industry that can greatly benefit from Unipress Tensioning Equipment is the construction industry. In construction projects, proper tensioning of cables, wires, and structural elements is crucial for ensuring the integrity and stability of buildings and infrastructure. With Unipress Tensioning Equipment, contractors can achieve accurate tension control, resulting in stronger structures and enhanced safety.

The manufacturing industry also stands to gain significant advantages from using Unipress Tensioning Equipment. Whether it’s in the production of automotive components, machinery parts, or even consumer goods like furniture or appliances, precise tension control plays a vital role in ensuring product quality and reliability. By utilizing this equipment, manufacturers can achieve consistent tension levels during assembly processes, leading to improved product performance and customer satisfaction.

Another sector that can benefit from Unipress Tensioning Equipment is the renewable energy industry. In wind turbine installations or solar panel arrays, proper tensioning of cables and guy wires is essential for maintaining structural integrity under varying weather conditions. With Unipress Tensioning Equipment’s advanced features such as real-time monitoring and automatic adjustment capabilities, renewable energy companies can ensure optimal tension levels for maximum efficiency and durability.

Furthermore, the transportation industry can also reap rewards from using Unipress Tensioning Equipment. Whether it’s in securing cargo on trucks or trailers or ensuring proper tension in railway tracks or overhead power lines for electric trains, this equipment offers reliable solutions that enhance safety standards while minimizing maintenance requirements.

In conclusion, Unipress Tensioning Equipment provides significant benefits across various industries by enabling precise tension control for different applications. From construction to manufacturing to renewable energy to transportation sectors – this innovative solution enhances performance, safety standards while improving overall operational efficiency.

What factors should be considered when choosing a tensioning machine?

When selecting a tensioning machine, there are several important factors that should be taken into consideration. These factors will help determine the suitability of the machine for your specific application requirements.

Firstly, it is crucial to assess the specifications of the tensioning machine. Consider factors such as maximum tension capacity, speed range, and adjustability options. These specifications should align with your specific needs to ensure optimal performance.

Ease of use is another key factor to consider. Look for a tensioning machine that offers intuitive controls and user-friendly interfaces. This will not only enhance productivity but also reduce the learning curve for operators.

Durability is also an essential aspect to evaluate when choosing a tensioning machine. Ensure that it is constructed from high-quality materials and designed to withstand heavy-duty usage over time. A durable machine will minimize downtime and maintenance costs in the long run.

Additionally, it is advisable to seek feedback from other users or industry experts who have experience with different tensioning machines. Their insights can provide valuable information on reliability, performance, and overall satisfaction with specific brands or models.

By considering these factors – specifications, ease of use, durability, and user feedback – you can make an informed decision when choosing a tensioning machine that best suits your application requirements.

What is the difference between manual and automated tensioning machines?

Manual tensioning machines, also known as hand-operated tensioners, are tools that require human effort to apply tension to a strapping material. These machines typically consist of a handle or lever that is manually operated to tighten the strap around the object being secured. Manual tensioning machines are commonly used in smaller-scale operations or situations where portability and simplicity are key.

On the other hand, automated tensioning machines, also referred to as pneumatic or electric tensioners, utilize mechanical or electrical power to apply tension to the strapping material. These machines often feature motors or compressed air systems that automate the process of tightening the strap. Automated tensioning machines are ideal for high-volume applications or scenarios where consistent and precise tensioning is required.

One key difference between manual and automated tensioning machines is the level of physical effort required. Manual tensioners rely on human strength and stamina, which can lead to fatigue over time. In contrast, automated machines reduce operator fatigue by taking over the physical exertion aspect of applying tension.

Another distinction lies in efficiency and speed. Manual tensioning machines usually have slower operation speeds compared to their automated counterparts. This can be a limiting factor in situations where time is crucial or when dealing with large volumes of strapping.

Additionally, automated tensioners often offer more advanced features such as adjustable settings for precise control over applied tensions, built-in safety mechanisms, and compatibility with various types and sizes of strapping materials.

Ultimately, choosing between manual and automated tensioning machines depends on factors such as workload volume, desired efficiency levels, budget considerations, and specific application requirements.

Contact Us

Contact Us About Tensioning Equipment

Send us a message for our team to review. We will respond promptly.